- Home

- Company Profile

- Products

- Industries

- Services

- Contact

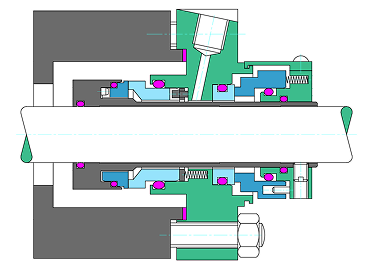

Product Code: DC20 Mechanical Seal

Double cartridge seals are pre-assembled, factory-tested dual sealing units that offer maximum reliability, safety, and performance for critical process applications. These seals are used where zero leakage, environmental compliance, or hazardous fluid containment is essential. They consist of two sets of seal faces (inner and outer), usually used in tandem, back-to-back, or face-to-face arrangements, with a buffer or barrier fluid circulating between them.

| Parameter | Standard Value / Range |

|---|---|

| Diameter | 25 mm to 75 mm (custom sizes available) |

| Max.Pres | Upto 20 bar |

| Barrier.Pres | 1.5 to 3 bar above process pressure |

| Temp. Range | -20°C to +180°C |

| Velocity | 20 m/s |

| Media | Abrasive, corrosive, flammable, or sterile media |